Preparation before installation:

-Perform a detailed parts list check to ensure that all necessary components are intact and undamaged.

-Accurately evaluate the installation environment to ensure the flatness and accessibility of the site, while reserving sufficient operating space.

-Prepare a comprehensive and professional tool kit, including but not limited to torque wrenches, level gauges, and necessary measuring tools, to ensure the accuracy and efficiency of the installation process.

Installation base:

-Place the pre assembled base in the designated position, ensuring it is stable and flat with the ground.

-Using precise positioning technology, the base is accurately positioned through laser measuring instruments or optical calibration methods to ensure the accuracy of subsequent component installation.

-Using high-strength bolts and precision thread locking technology, the fixing operation is carried out according to the manufacturer's recommended torque specifications to ensure the stability and durability of the base under various working conditions.

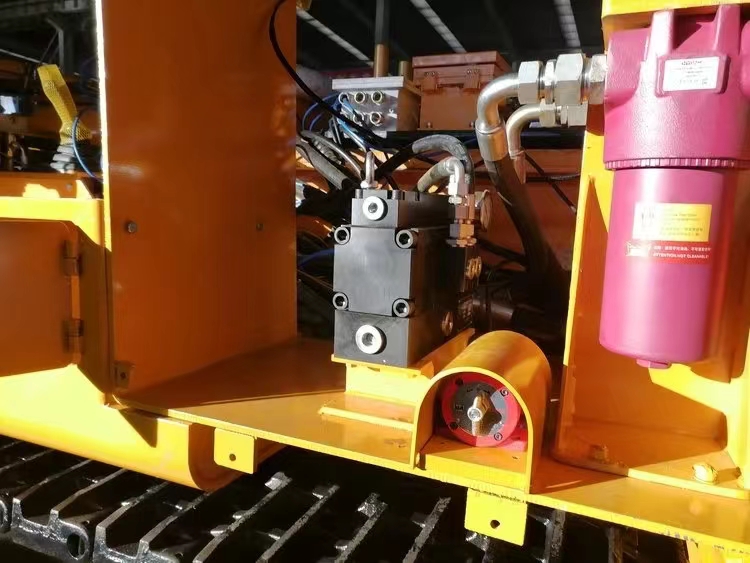

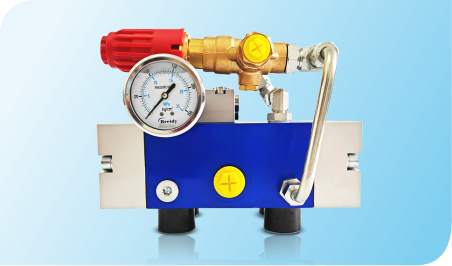

Connecting pipeline:

-Precision docking is carried out on the inlet and outlet to ensure a tight and seamless interface between the pipeline and the pump body. High quality flanges and wear-resistant sealing gaskets are used to prevent medium leakage.

-Implement strict stress testing procedures, inspect all connection points one by one to ensure no leakage occurs under the design working pressure, and record test data as the basis for quality control.

Install the motor and transmission components:

-Accurately align and install the motor drive unit to ensure perfect alignment of its axis with the pump body. Use advanced dynamic balance measurement technology to calibrate the rotating part of the motor to optimize smooth operation and reduce vibration levels.

-Adopting coupling installation procedures that comply with international standards to ensure maximum torque transmission efficiency of the coupling, while reserving appropriate preload force to adapt to changes in the subsequent working environment.

Electrical connection:

-Adhere to strict electrical installation standards, follow the wiring diagram provided by the manufacturer for cable routing, ensure all wire connections are correct and error free, use high-quality connectors and insulation materials, and avoid potential electrical failure risks.

-Implement comprehensive electrical safety inspections, including testing of grounding systems, measurement of insulation strength, and functional verification of electrical components, to ensure the reliability of the entire electrical system and compliance with industry safety standards.

Debugging and testing:

-Conduct a system level pre start inspection after installation, including a detailed review of the range of motion of all mechanical components, the torque condition of fasteners, and the response performance of the electrical system.

-Conduct comprehensive performance testing, simulate actual working conditions, and record key operating parameters such as flow rate, head, and power consumption through precise flow meters and pressure sensors to ensure that the system meets or exceeds expected performance indicators.

Maintenance and inspection:

-Establish a standardized maintenance plan, regularly clean and maintain the inside and outside of the pump body, use professional cleaning agents and protective coatings to resist the erosion of corrosive media, and check the wear level of all vulnerable parts.

-Implement preventive maintenance measures, including regular lubrication of sealing systems, bearings, and transmission components, as well as fastening and cleaning of electrical connections, to ensure long-term stable operation of the equipment, and timely replacement of severely worn components to avoid unexpected shutdowns.

HPW series hydraulic high-pressure water pump

HPW200/30-45 、HPW200/30-45-ST、 HPW420/20-50-PA 、HPW420/20-50-PA、HPW220/50-70、HPW220/50-70-PA、HPW220/50-70MOBI、HPW90/150-85、HPW90/150-85-PA、HPW520/30-85、HPW520/30-85-PA、HPW180/90-115、HPW320/75-115、HPW800/30-140

HPW200/30-45 、HPW200/30-45-ST、 HPW420/20-50-PA 、HPW420/20-50-PA、HPW220/50-70、HPW220/50-70-PA、HPW220/50-70MOBI、HPW90/150-85、HPW90/150-85-PA、HPW520/30-85、HPW520/30-85-PA、HPW180/90-115、HPW320/75-115、HPW800/30-140

HPW200/30-45 、HPW200/30-45-ST、 HPW420/20-50-PA 、HPW420/20-50-PA、HPW220/50-70、HPW220/50-70-PA、HPW220/50-70MOBI、HPW90/150-85、HPW90/150-85-PA、HPW520/30-85、HPW520/30-85-PA、HPW180/90-115、HPW320/75-115、HPW800/30-140

HDF series hydraulic high-pressure water pump

HDF20/60、HDF50/45、HDF80/100、HDF80/160、HDF80/180、HDF80/250、HDF80/320、HDF80/450、HDF520/30、HDF90/150、HDF80/500、HDF200/100、HDF20/250、HDF100/600、HDF100/1200、HDF1200/100、HDF600/200、HDF180/23-35

HDF20/60、HDF50/45、HDF80/100、HDF80/160、HDF80/180、HDF80/250、HDF80/320、HDF80/450、HDF520/30、HDF90/150、HDF80/500、HDF200/100、HDF20/250、HDF100/600、HDF100/1200、HDF1200/100、HDF600/200、HDF180/23-35

HDF20/60、HDF50/45、HDF80/100、HDF80/160、HDF80/180、HDF80/250、HDF80/320、HDF80/450、HDF520/30、HDF90/150、HDF80/500、HDF200/100、HDF20/250、HDF100/600、HDF100/1200、HDF1200/100、HDF600/200、HDF180/23-35

|

|

返回

返回